Metalworking is the process of working with metals to create individual parts, assemblies, or large scale structures. The term covers a wide range of work from large ships and bridges to precise engine parts and delicate jewelry. It therefore includes a correspondingly wide range of skills, processes, and tools.

Metalworking is a science, art, hobby, industry and trade. Its historical roots span cultures, civilizations, and millennia. Metalworking has evolved from the discovery of smelting various ores, producing malleable and ductile metal useful for tools and adornments. Modern metalworking processes, though diverse and specialized, can be categorized as forming, cutting or joining processes. Today's machine shop includes a number of machine tools capable of creating a precise, useful workpiece.

Not all metal required fire to obtain it or work it. Isaac Asimov speculated that gold was the "first metal."[1] His reasoning is that gold by its chemistry is found in nature as nuggets of pure gold. In other words, gold, as rare as it is, is always found in nature as the metal that it is. There are a few other metals that sometimes occur natively, and as a result of meteors. Almost all other metals are found in ores, a mineral bearing rock, that require heat or some other process to liberate the metal. Another feature of gold is that it is workable as it is found, meaning that no technology beyond eyes to find a nugget and a hammer and an anvil to work the metal is needed. Stone hammer and stone anvil will suffice for technology. This is the result of gold's properties of malleability and ductility. The earliest tools were stone, bone, wood, and sinew. They sufficed to work gold.

At some unknown point the connection between heat and the liberation of metals from rock became clear, rocks rich in copper, tin, and lead came into demand. These ores were mined wherever they were recognized. Remnants of such ancient mines have been found all over what is today the Middle East.[2] Metalworking was being carried out by the South Asian inhabitants of Mehrgarh between 7000–3300 BCE.[3] The end of the beginning of metalworking occurs sometime around 6000 BCE when copper smelting became common in the Middle East.

The ancients knew of seven metals. Here they are arranged in order of their oxidation potential:

The oxidation potential is important because it is one indicator of how tightly bound to the ore the metal is likely to be. As can be seen, iron is significantly higher than the other six metals while gold is dramatically lower than the six above it. Gold's low oxidation is one of the main reasons that gold is found in nuggets. These nuggets are relatively pure gold and are workable as they are found.

Copper ore, being relatively abundant, and tin ore became the next important players in the story of metalworking. Using heat to smelt copper from ore, a great deal of copper was produced. It was used for both jewelry and simple tools. However, copper by itself was too soft for tools requiring edges and stiffness. At some point tin was added into the molten copper and bronze was born. Bronze is an alloy of copper and tin. Bronze was an important advance because it had the edge-durability and stiffness that pure copper lacked. Until the advent of iron, bronze was the most advanced metal for tools and weapons in common use (see Bronze Age for more detail).

Looking beyond the Middle East, these same advances and materials were being discovered and used the world around. China and Britain jumped into the use of bronze with little time being devoted to copper. Japan began the use of bronze and iron almost simultaneously. In the Americas things were different. Although the peoples of the Americas knew of metals, it wasn't until the arrival of Europeans that metal for tools and weapons took off. Jewelry and art were the principal uses of metals in the Americas prior to European influence.

Around the date 2700 BCE, production of bronze was common in locales where the necessary materials could be assembled for smelting, heating, and working the metal. Iron was beginning to be smelted. Iron began its emergence as an important metal for tools and weapons. The Iron Age was dawning.

By the historical periods of the Pharaohs in Egypt, the Vedic Kings in India, the Tribes of Israel, and the Mayan Civilization in North America, among other ancient populations, precious metals began to have value attached to them. In some cases rules for ownership, distribution, and trade were created, enforced, and agreed upon by the respective peoples. By the above periods metalworkers were very skilled at creating objects of adornment, religious artifacts, and trade instruments of precious metals (non-ferrous), as well as weaponry usually of ferrous metals and/or alloys. These skills were finely honed and well executed. The techniques were practiced by artisans, blacksmiths, atharvavedic practitioners, alchemists, and other categories of metalworkers around the globe. For example, the ancient technique of granulation is found around the world in numerous ancient cultures before the historic record shows people traveled seas or overland to far regions of the earth to share this process that still being used by metalsmiths today.

As time progressed metal objects became more common, and ever more complex. The need to further acquire and work metals grew in importance. Skills related to extracting metal ores from the earth began to evolve, and metalsmiths became more knowledgeable. Metalsmiths became important members of society. Fates and economies of entire civilizations were greatly affected by the availability of metals and metalsmiths. The metalworker depends on the extraction of precious metals to make jewelry, build more efficient electronics, and for industrial and technological applications from construction to shipping containers to rail, and air transport. Without metals, goods and services would cease to move around the globe on the scale we know today.

More individuals than ever before are learning metalworking as a creative outlet in the forms of jewelry making, hobby restoration of aircraft and cars, blacksmithing, tinsmithing, tinkering, and in other art and craft pursuits. Trade schools continue to teach welding in all of its forms, and there is a proliferation of schools of Lapidary and Jewelers arts and sciences at this- the beginning of the 21st Century AD.

Metalworking generally is divided into the following categories, forming, cutting, and, joining. Each of these categories contain various processes.

Metalworking generally is divided into the following categories, forming, cutting, and, joining. Each of these categories contain various processes.

Prior to most operations, the metal must be marked out and/or measured, depending on the desired finished product.

Marking out (also known as layout) is the process of transferring a design or pattern to a workpiece and is the first step in the handcraft of metalworking. It is performed in many industries or hobbies, although in the repetition industries the need to mark out every individual piece is eliminated. In the metal trades area, marking out consists of transferring the engineer's plan to the workpiece in preparation for the next step, machining or manufacture.

Calipers are hand tools designed to precisely measure the distance between two points. Most calipers have two sets of flat, perpendicular edges used for inner or outer diameter. These calipers can be accurate to within one-thousandth of an inch (25.4μm). Different types of calipers have different mechanisms for displaying the distance measured. Where larger objects need to be measured with less precision, a tape measure is often used.

Cutting is nearly fully represented by:

There are many technologies available to cut metal, including:

The pieces produced are usually complex 3D objects that are converted into x, y, and z coordinates that are then fed into the CNC machine and allow it to complete the tasks required. The milling machine can produce most parts in 3D, but some require the objects to be rotated around the x, y, or z coordinate axis (depending on the need). Tolerances are usually in the thousandths of an inch (Unit known as Thou), depending on the specific machine.

In order to keep both the bit and material cool, a high temperature coolant is used. In most cases the coolant is sprayed from a hose directly onto the bit and material. This coolant can either be machine or user controlled, depending on the machine.

Materials that can be milled range from aluminum to stainless steel and most everything in between. Each material requires a different speed on the milling tool and varies in the amount of material that can be removed in one pass of the tool. Harder materials are usually milled at slower speeds with small amounts of material removed. Softer materials vary, but usually are milled with a high bit speed.

The use of a milling machine adds costs that are factored into the manufacturing process. Each time the machine is used coolant is also used, which must be periodically added in order to prevent breaking bits. A milling bit must also be changed as needed in order to prevent damage to the material. Time is the biggest factor for costs. Complex parts can require hours to complete, while very simple parts take only minutes. This in turn varies the production time as well, as each part will require different amounts of time.

Safety is key with these machines. The bits are traveling at high speeds and removing pieces of usually scalding hot metal. The advantage of having a CNC milling machine is that it protects the machine operator.

Metalworking is a science, art, hobby, industry and trade. Its historical roots span cultures, civilizations, and millennia. Metalworking has evolved from the discovery of smelting various ores, producing malleable and ductile metal useful for tools and adornments. Modern metalworking processes, though diverse and specialized, can be categorized as forming, cutting or joining processes. Today's machine shop includes a number of machine tools capable of creating a precise, useful workpiece.

Contents[hide] |

[edit] Prehistory

Metalworking predates history. No one knows with any certainty where or when metalworking began. The earliest technologies were impermanent and were unlikely to leave evidence for long. The advance that brought metal into focus was the connection of fire and metals. Who accomplished this is as unknown as the when and where, but the Egyptians are thought to have been one of the first civilizations to work gold.Not all metal required fire to obtain it or work it. Isaac Asimov speculated that gold was the "first metal."[1] His reasoning is that gold by its chemistry is found in nature as nuggets of pure gold. In other words, gold, as rare as it is, is always found in nature as the metal that it is. There are a few other metals that sometimes occur natively, and as a result of meteors. Almost all other metals are found in ores, a mineral bearing rock, that require heat or some other process to liberate the metal. Another feature of gold is that it is workable as it is found, meaning that no technology beyond eyes to find a nugget and a hammer and an anvil to work the metal is needed. Stone hammer and stone anvil will suffice for technology. This is the result of gold's properties of malleability and ductility. The earliest tools were stone, bone, wood, and sinew. They sufficed to work gold.

At some unknown point the connection between heat and the liberation of metals from rock became clear, rocks rich in copper, tin, and lead came into demand. These ores were mined wherever they were recognized. Remnants of such ancient mines have been found all over what is today the Middle East.[2] Metalworking was being carried out by the South Asian inhabitants of Mehrgarh between 7000–3300 BCE.[3] The end of the beginning of metalworking occurs sometime around 6000 BCE when copper smelting became common in the Middle East.

The ancients knew of seven metals. Here they are arranged in order of their oxidation potential:

The oxidation potential is important because it is one indicator of how tightly bound to the ore the metal is likely to be. As can be seen, iron is significantly higher than the other six metals while gold is dramatically lower than the six above it. Gold's low oxidation is one of the main reasons that gold is found in nuggets. These nuggets are relatively pure gold and are workable as they are found.

Copper ore, being relatively abundant, and tin ore became the next important players in the story of metalworking. Using heat to smelt copper from ore, a great deal of copper was produced. It was used for both jewelry and simple tools. However, copper by itself was too soft for tools requiring edges and stiffness. At some point tin was added into the molten copper and bronze was born. Bronze is an alloy of copper and tin. Bronze was an important advance because it had the edge-durability and stiffness that pure copper lacked. Until the advent of iron, bronze was the most advanced metal for tools and weapons in common use (see Bronze Age for more detail).

Looking beyond the Middle East, these same advances and materials were being discovered and used the world around. China and Britain jumped into the use of bronze with little time being devoted to copper. Japan began the use of bronze and iron almost simultaneously. In the Americas things were different. Although the peoples of the Americas knew of metals, it wasn't until the arrival of Europeans that metal for tools and weapons took off. Jewelry and art were the principal uses of metals in the Americas prior to European influence.

Around the date 2700 BCE, production of bronze was common in locales where the necessary materials could be assembled for smelting, heating, and working the metal. Iron was beginning to be smelted. Iron began its emergence as an important metal for tools and weapons. The Iron Age was dawning.

[edit] History

See also: History of ferrous metallurgy

As time progressed metal objects became more common, and ever more complex. The need to further acquire and work metals grew in importance. Skills related to extracting metal ores from the earth began to evolve, and metalsmiths became more knowledgeable. Metalsmiths became important members of society. Fates and economies of entire civilizations were greatly affected by the availability of metals and metalsmiths. The metalworker depends on the extraction of precious metals to make jewelry, build more efficient electronics, and for industrial and technological applications from construction to shipping containers to rail, and air transport. Without metals, goods and services would cease to move around the globe on the scale we know today.

More individuals than ever before are learning metalworking as a creative outlet in the forms of jewelry making, hobby restoration of aircraft and cars, blacksmithing, tinsmithing, tinkering, and in other art and craft pursuits. Trade schools continue to teach welding in all of its forms, and there is a proliferation of schools of Lapidary and Jewelers arts and sciences at this- the beginning of the 21st Century AD.

[edit] General metalworking processes

A combination square used for transferring designs.

| Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Process | Iron | Steel | Aluminium | Copper | Magnesium | Nickel | Refractory metals | Titanium | Zinc |

| Sand casting | X | X | X | X | X | X | 0 | ||

| Permanent mold casting | X | 0 | X | 0 | X | 0 | 0 | ||

| Die casting | X | 0 | X | X | |||||

| Investment casting | X | X | X | 0 | 0 | ||||

| Closed-die forging | X | 0 | 0 | 0 | 0 | 0 | 0 | ||

| Extrusion | 0 | X | X | X | 0 | 0 | 0 | ||

| Cold heading | X | X | X | 0 | |||||

| Stamping & deep drawing | X | X | X | 0 | X | 0 | 0 | ||

| Screw machine | 0 | X | X | X | 0 | X | 0 | 0 | 0 |

| Powder metallurgy | X | X | 0 | X | 0 | X | 0 | ||

| Key: X = Routinely performed, 0 = Performed with difficulty, caution, or some sacrifice, blank = Not recommended | |||||||||

Marking out (also known as layout) is the process of transferring a design or pattern to a workpiece and is the first step in the handcraft of metalworking. It is performed in many industries or hobbies, although in the repetition industries the need to mark out every individual piece is eliminated. In the metal trades area, marking out consists of transferring the engineer's plan to the workpiece in preparation for the next step, machining or manufacture.

Calipers are hand tools designed to precisely measure the distance between two points. Most calipers have two sets of flat, perpendicular edges used for inner or outer diameter. These calipers can be accurate to within one-thousandth of an inch (25.4μm). Different types of calipers have different mechanisms for displaying the distance measured. Where larger objects need to be measured with less precision, a tape measure is often used.

[edit] Forming processes

These forming processes modify metal or workpiece by deforming the object, that is, without removing any material. Forming is done with heat and pressure, or with mechanical force, or both.[edit] Casting

Main article: Metal casting

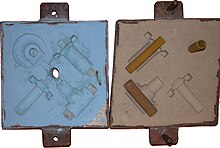

Casting achieves a specific form by pouring molten metal into a mold and allowing it to cool, with no mechanical force. Forms of casting include:- Investment casting (called lost wax casting in art)

- Centrifugal casting

- Die casting

- Sand casting

- Shell casting

- Spin casting

[edit] Plastic deforming

Plastic deformation involves using heat or pressure to make a workpiece more conductive to mechanical force. Historically, this and casting were done by blacksmiths, though today the process has been industrialized.[edit] Sheet metal forming

See also: Sheet metal

These types of forming process involve the application of mechanical force at room temperature.- Bending

- Coining

- Decambering

- Deep drawing

- Drawing

- Spinning

- Flow turning

- Raising

- Roll forming

- Roll bending

- Repoussé and chasing

- Rolling

- Rubber pad forming

- Shearing

- Stamping

- Wheeling using an English wheel (wheeling machine)

[edit] Cutting processes

Main article: Cutting

Cutting is a collection of processes wherein material is brought to a specified geometry by removing excess material using various kinds of tooling to leave a finished part that meets specifications. The net result of cutting is two products, the waste or excess material, and the finished part. If this were a discussion of woodworking, the waste would be sawdust and excess wood. In cutting metals the waste is chips or swarf and excess metal. These processes can be divided into chip producing cutting, generally known as machining. Burning or cutting with an oxyfuel torch is a welding process not machining. There are also miscellaneous specialty processes such as chemical milling.Cutting is nearly fully represented by:

- Chip producing processes most commonly known as machining

- Burning, a set of processes which cut by oxidizing a kerf to separate pieces of metal

- Specialty processes

There are many technologies available to cut metal, including:

- Manual technologies: saw, chisel, shear or snips

- Machine technologies: turning, milling, drilling, grinding, sawing

- Welding/burning technologies: burning by laser, oxy-fuel burning, and plasma

- Erosion technologies:by water jet or electric discharge.

[edit] Machining

Main article: Machining

Milling is the complex shaping of metal or other materials by removing material to form the final shape. It is generally done on a milling machine, a power-driven machine that in its basic form consists of a milling cutter that rotates about the spindle axis (like a drill), and a worktable that can move in multiple directions (usually two dimensions [x and y axis] relative to the workpiece). The spindle usually moves in the z axis. It is possible to raise the table (where the workpiece rests). Milling machines may be operated manually or under computer numerical control (CNC), and can perform a vast number of complex operations, such as slot cutting, planing, drilling and threading, rabbeting, routing, etc. Two common types of mills are the horizontal mill and vertical mill.The pieces produced are usually complex 3D objects that are converted into x, y, and z coordinates that are then fed into the CNC machine and allow it to complete the tasks required. The milling machine can produce most parts in 3D, but some require the objects to be rotated around the x, y, or z coordinate axis (depending on the need). Tolerances are usually in the thousandths of an inch (Unit known as Thou), depending on the specific machine.

In order to keep both the bit and material cool, a high temperature coolant is used. In most cases the coolant is sprayed from a hose directly onto the bit and material. This coolant can either be machine or user controlled, depending on the machine.

Materials that can be milled range from aluminum to stainless steel and most everything in between. Each material requires a different speed on the milling tool and varies in the amount of material that can be removed in one pass of the tool. Harder materials are usually milled at slower speeds with small amounts of material removed. Softer materials vary, but usually are milled with a high bit speed.

The use of a milling machine adds costs that are factored into the manufacturing process. Each time the machine is used coolant is also used, which must be periodically added in order to prevent breaking bits. A milling bit must also be changed as needed in order to prevent damage to the material. Time is the biggest factor for costs. Complex parts can require hours to complete, while very simple parts take only minutes. This in turn varies the production time as well, as each part will require different amounts of time.

Safety is key with these machines. The bits are traveling at high speeds and removing pieces of usually scalding hot metal. The advantage of having a CNC milling machine is that it protects the machine operator.

No comments:

Post a Comment